Machine Data Acquisition (MDA)

Efficient Machine Data Acquisition: Potential and Challenges

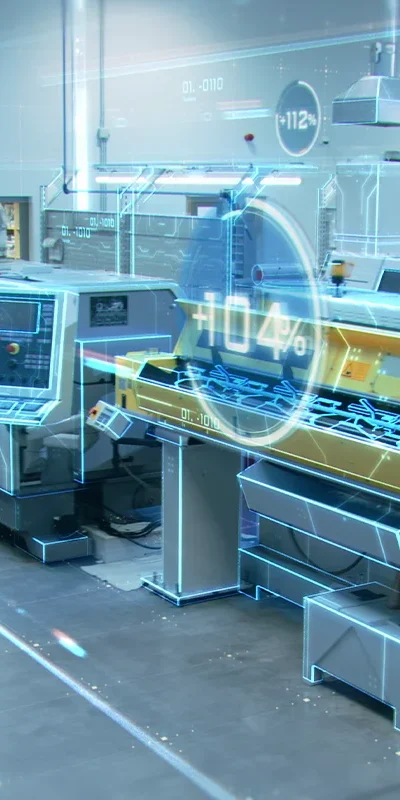

Machine data acquisition (MDA) enables the automatic capture and analysis of production data in real time. This can increase efficiency, reduce downtime and improve maintenance planning, among other things. A key challenge is the integration of heterogeneous machine parks with different interfaces and protocols. Furthermore, processing large amounts of data requires powerful IT infrastructures. Data protection and cybersecurity also play a crucial role, depending on the industry. Despite these hurdles, MDA is a key to digital transformation and competitiveness in industry.

The Benefits at a Glance

Machine data acquisition (MDA) offers numerous advantages for industry. The automated recording of operating and performance data minimizes downtime, optimizes production processes and proactively plans maintenance measures. Real-time analytics generally enable greater efficiency and better resource utilization.

At a Glance

- Brings transparency to production

- Cost reduction

- Higher throughput

- Improved planning through more accurate data

- Enables systematic troubleshooting and the implementation of targeted improvement measures

- Improves maintenance planning

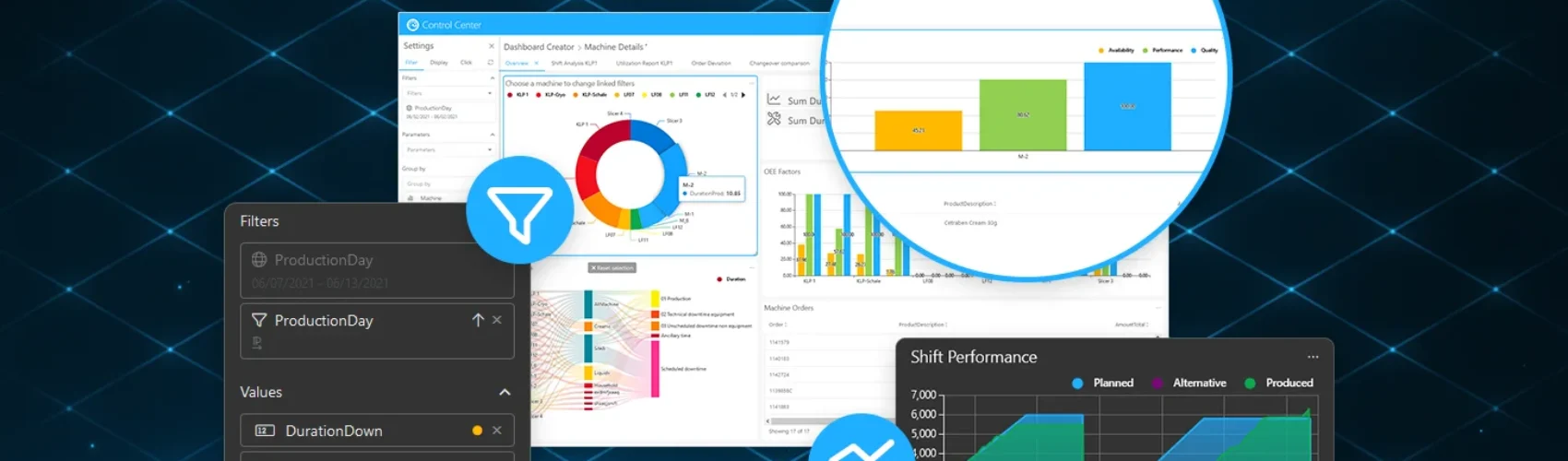

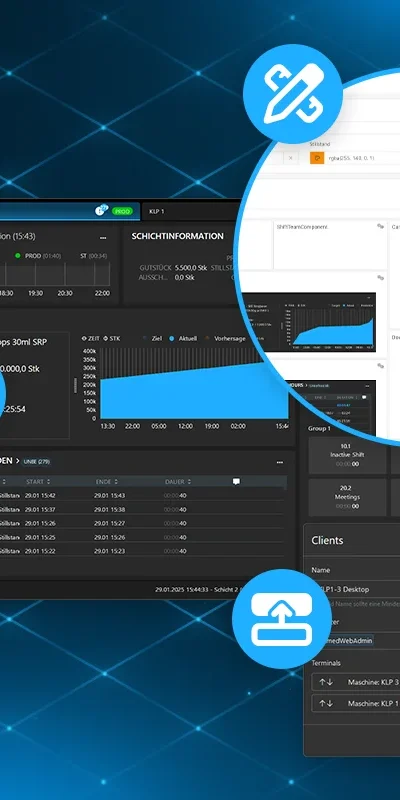

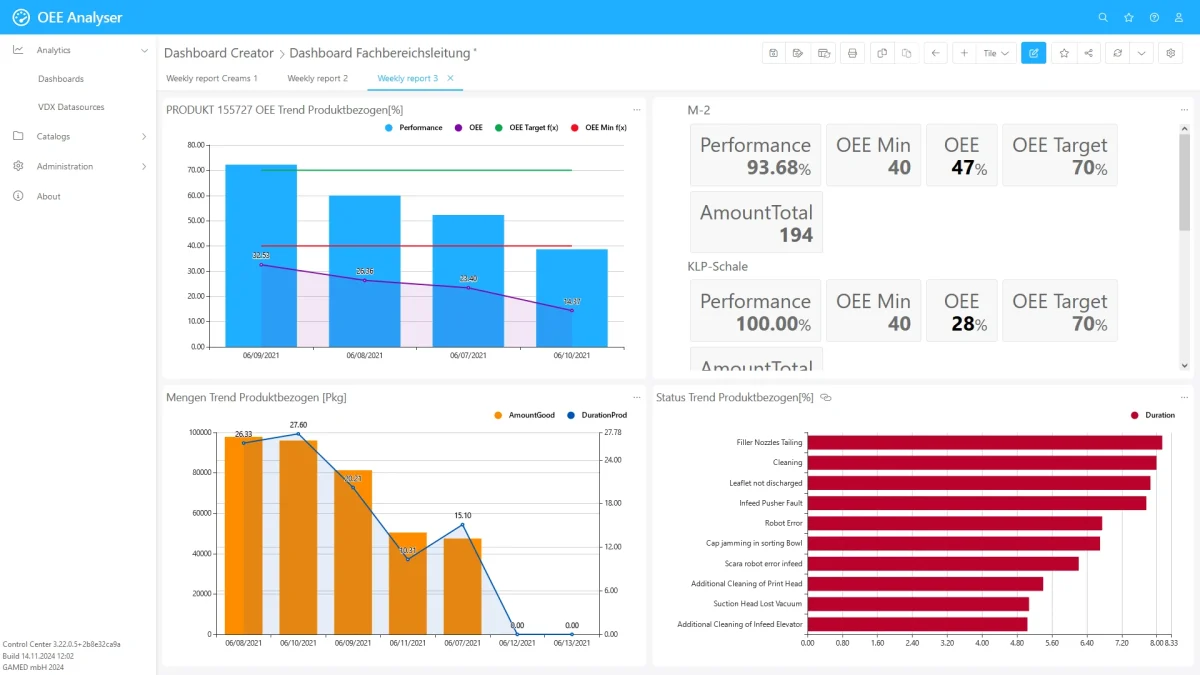

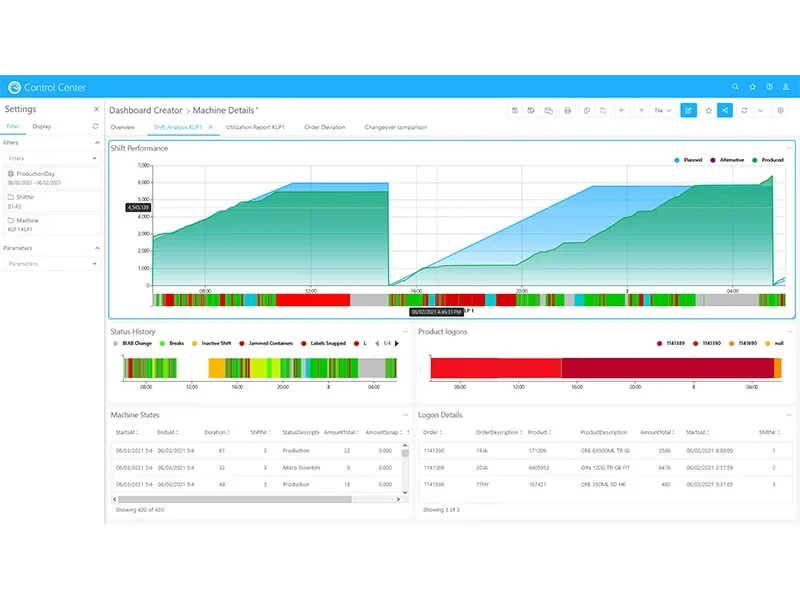

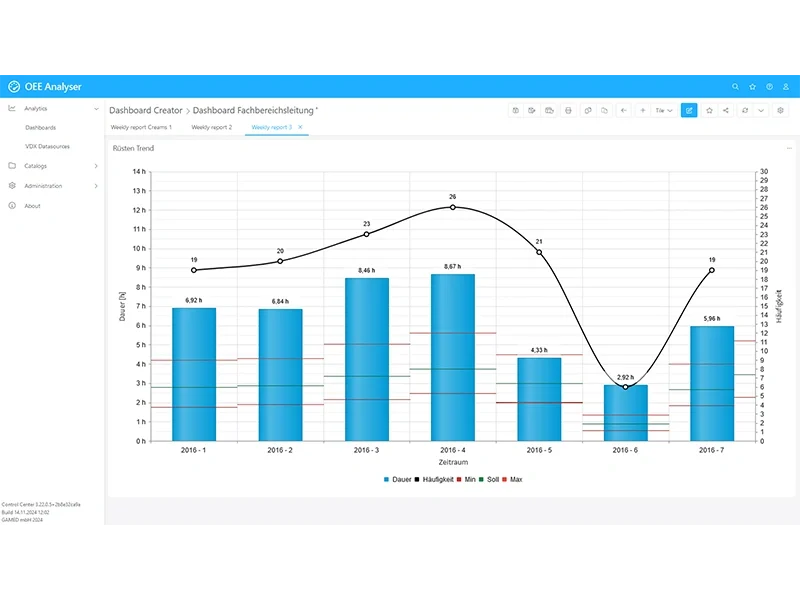

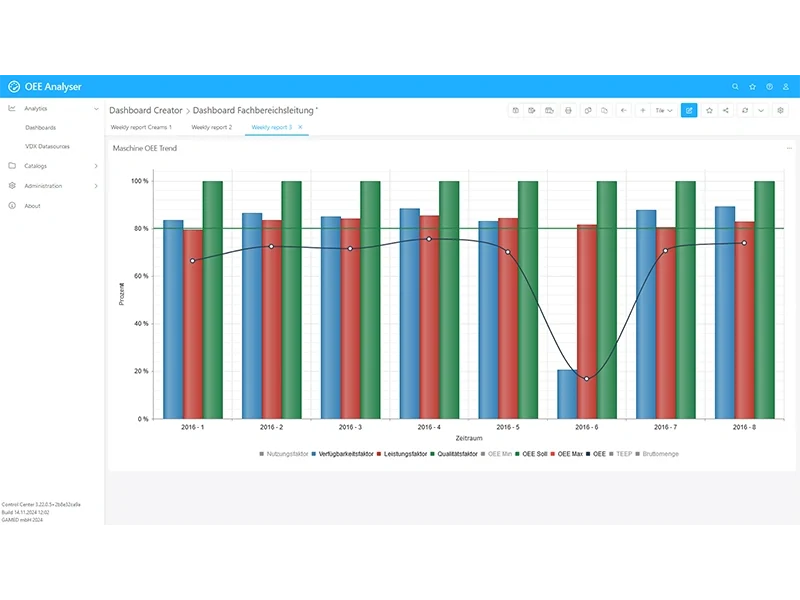

Functions and Features

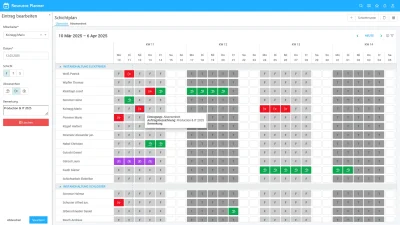

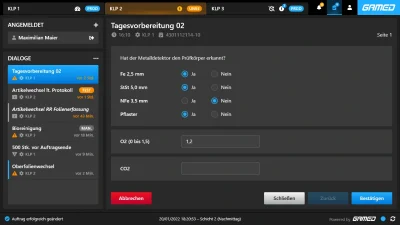

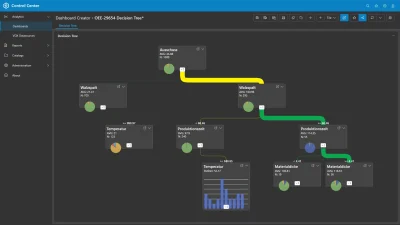

- Target definition

- Order tracking

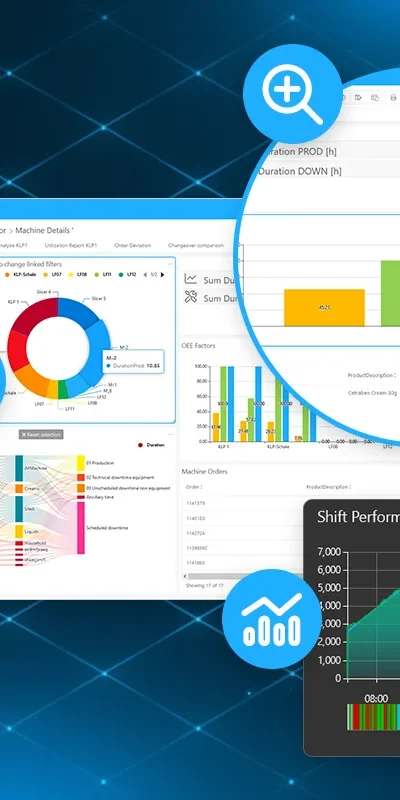

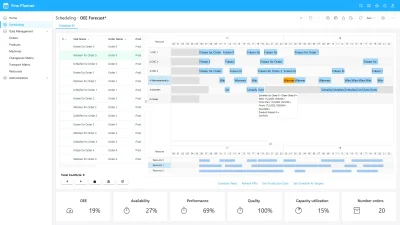

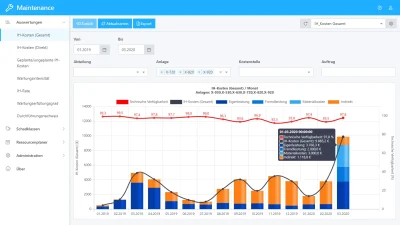

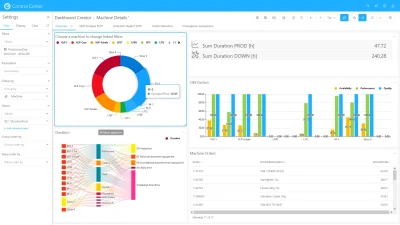

- Continuous OEE/TEEP determination

- Visualization with loss causes

- Downtime and scrap analysis

- OEE per product/order

- Processing time analysis

- Setup time evaluations

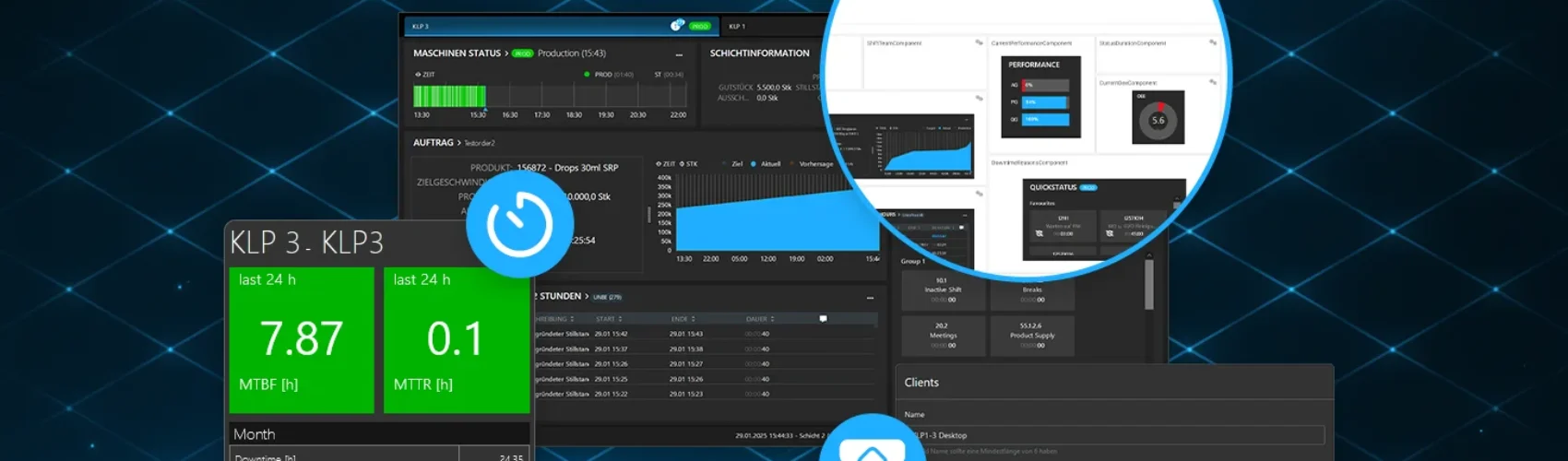

- MTBF-MTTR-MTBM trend

- Shift history, production report

- Machine status overview

- Correlation analysis

- Andon board

“Thanks to the solutions from GAMED, we were able to improve our processes considerably and thus significantly increase the efficiency of our production. The simple integration and reliable performance of the tools used convinced us just as much as the targeted and solution-orientated implementation of the project team.”

DI Silvia Schneller Deputy Operations Manager

I Will Be Happy to Help You

Philipp Seibald

Head of Business Development