Maintenance Management

Downtime Isn’t an Option – Right?

Smooth operations are essential in manufacturing companies, but without maintenance software, maintenance management quickly becomes a challenge. Information about machine conditions is often managed manually or in a scattered manner, leading to missed preventive maintenance and increased failure frequency. A lack of overview leads to unplanned downtime, high costs and inefficient processes. Without clear data, many things remain unpredictable – a risky situation in a highly competitive market where downtime not only jeopardizes processes but also profits.

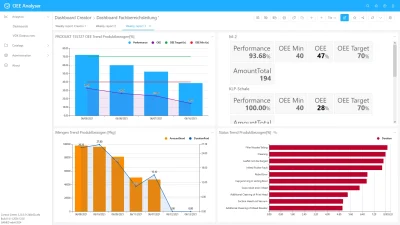

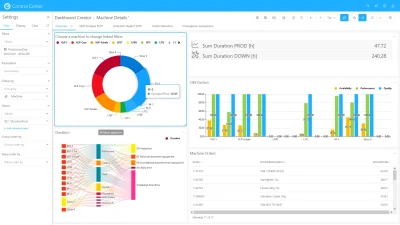

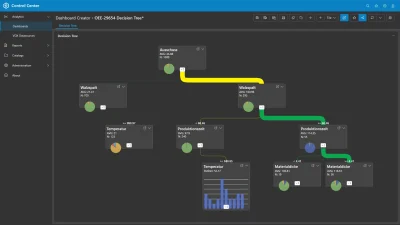

Advantages of Maintenance Software

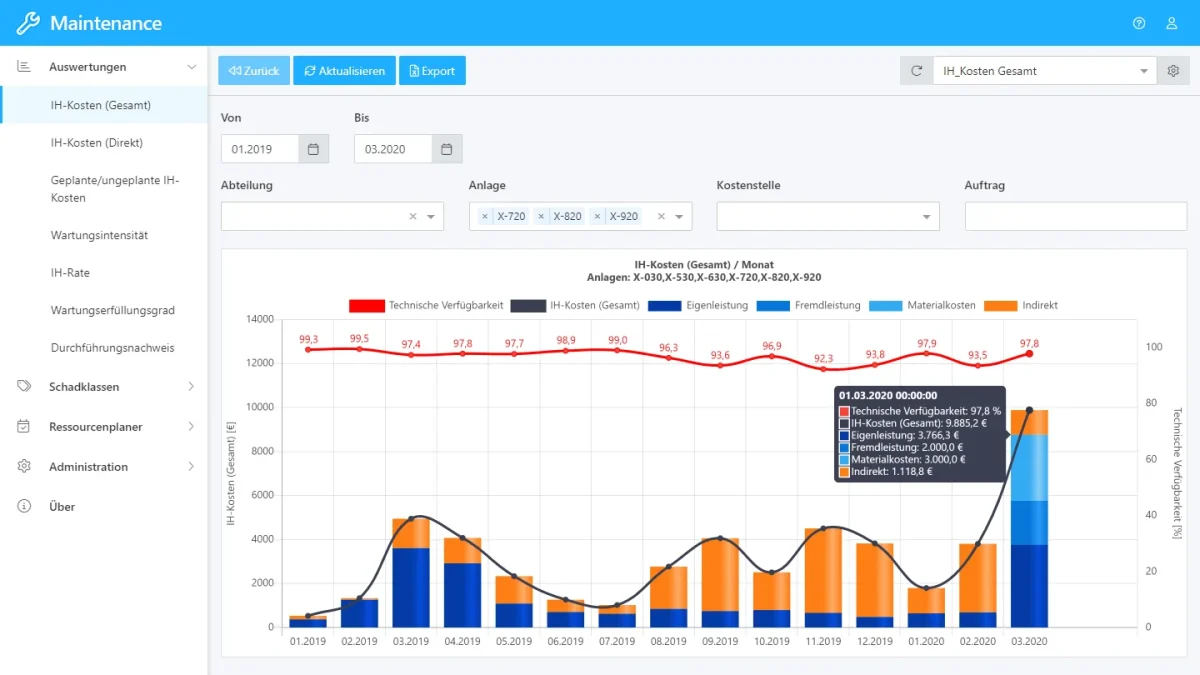

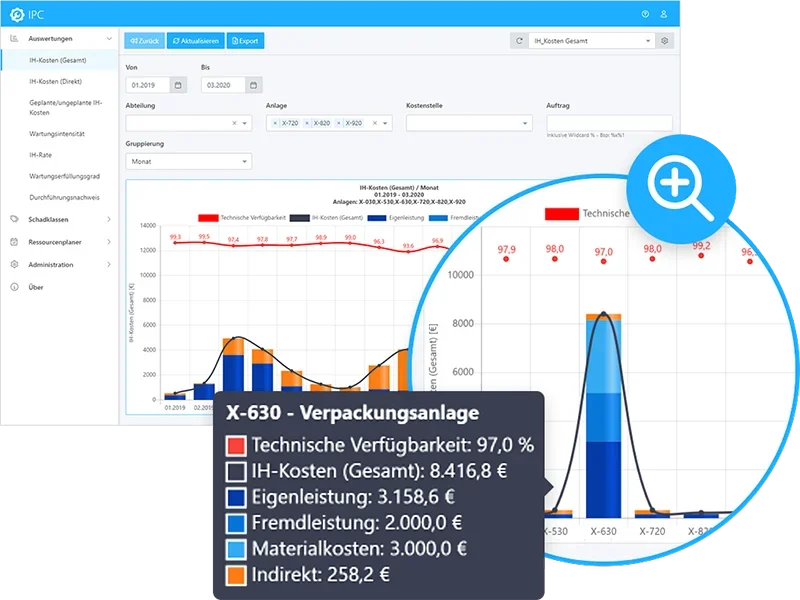

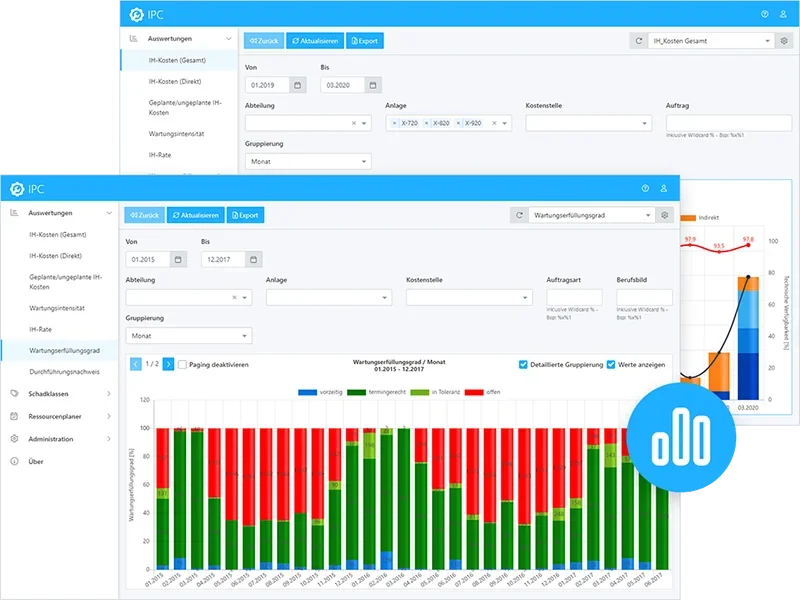

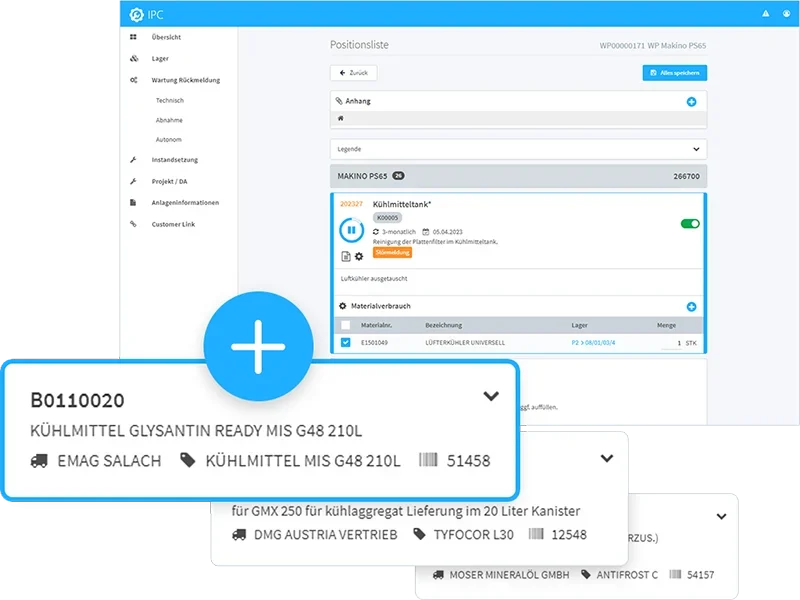

The implementation of maintenance software revolutionises maintenance in manufacturing companies. It creates transparency by centrally managing machine status and maintenance schedules. Real-time analysis enables preventative measures, reduces failures and lowers downtime costs. Comprehensive documentation facilitates certification, while key performance indicators and evaluations support strategic alignment. Integrated TPM promotes continuous process optimisation, sustainably increasing efficiency and competitiveness.

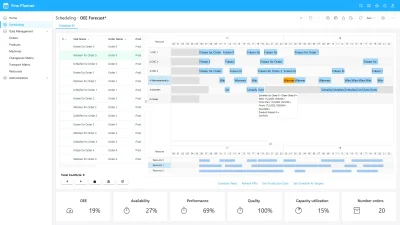

Economic Benefits

- Increased plant availability

- Improved planning and coordination

- Sustainable implementation of TPM

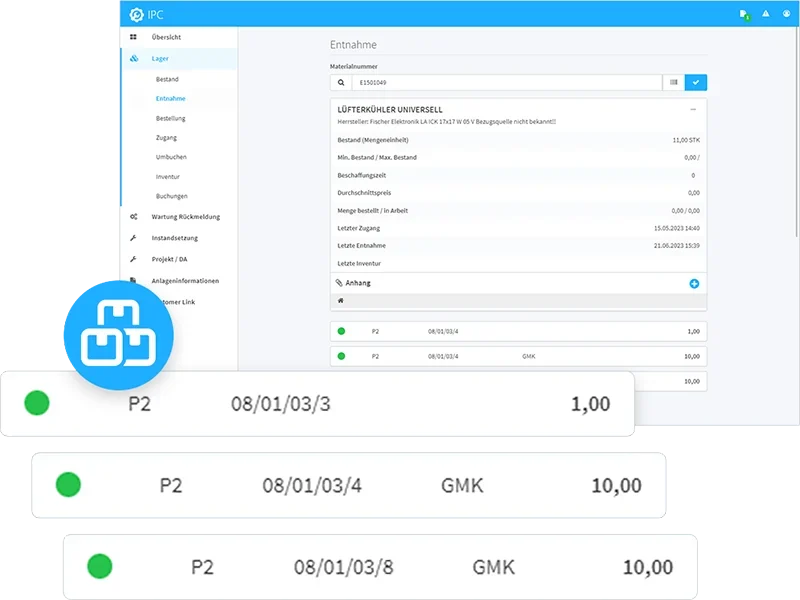

- Reduction in search and idle times

- Optimised material inventories and ordering processes

- Systematic plant improvements

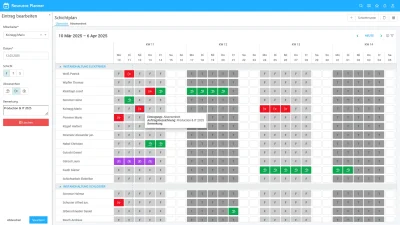

The Advantages at a Glance

- Rapid implementation

- Proven in various industries

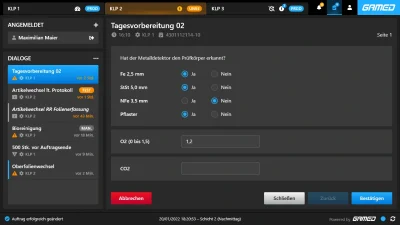

- Practical operation for maintenance staff

- Management information

- Use of mobile devices

- Integration into existing IT landscape

- Transfer of legacy data

“Our maintenance software ensures that maintenance is not just reactive but strategically planned. Real-time data, clear processes and automated workflows help our customers to minimise downtime, reduce costs and extend the service life of their systems in the long term.”

Martin Stimpfl CEO

I Will Be Happy to Help You

Philipp Seibald

Head of Business Development