Quality Management (QM)

Cross-departmental support

In-Process Checks

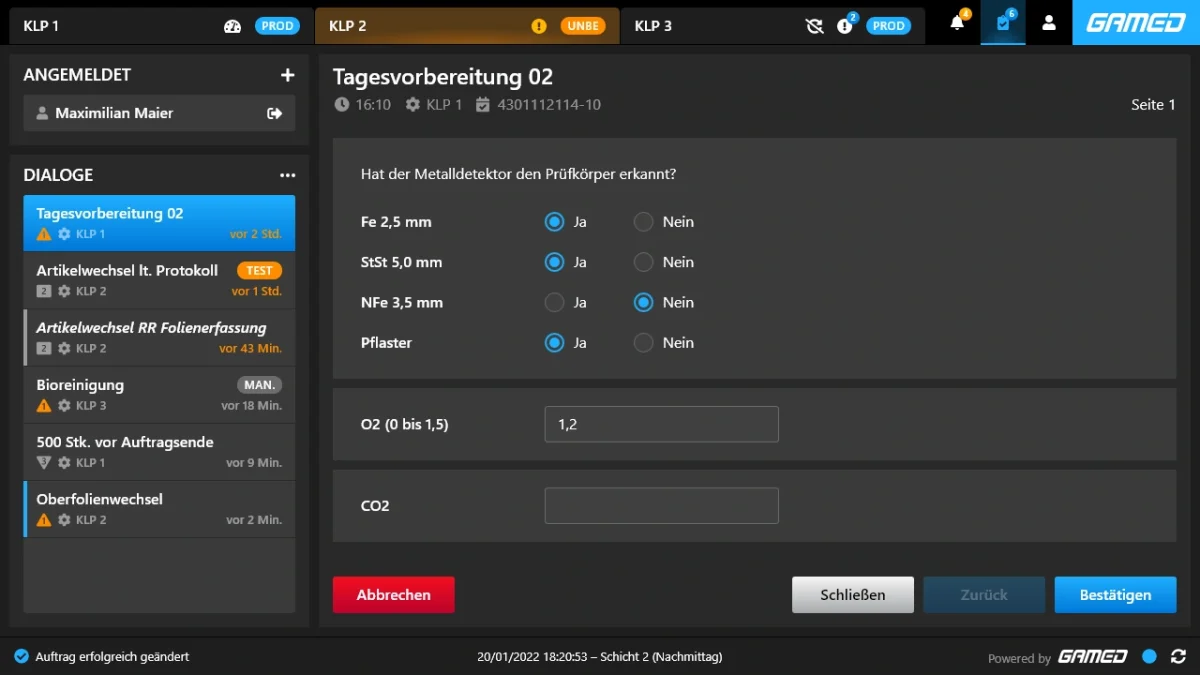

Manufacturing companies must conduct in-process checks in a legally compliant and reliable manner. Many still rely on manual solutions such as paper forms or Excel spreadsheets – an approach that often reaches its limits. High time expenditure, susceptibility to errors and a lack of transparency complicate traceability and slow down processes. Without real-time data, there is no overview and problems are often identified too late. The result: an inefficient, resource-intensive process. Our solution uses live data for maximum control, greater efficiency and future-proof production.

Manufacture High-Quality Products Without Errors

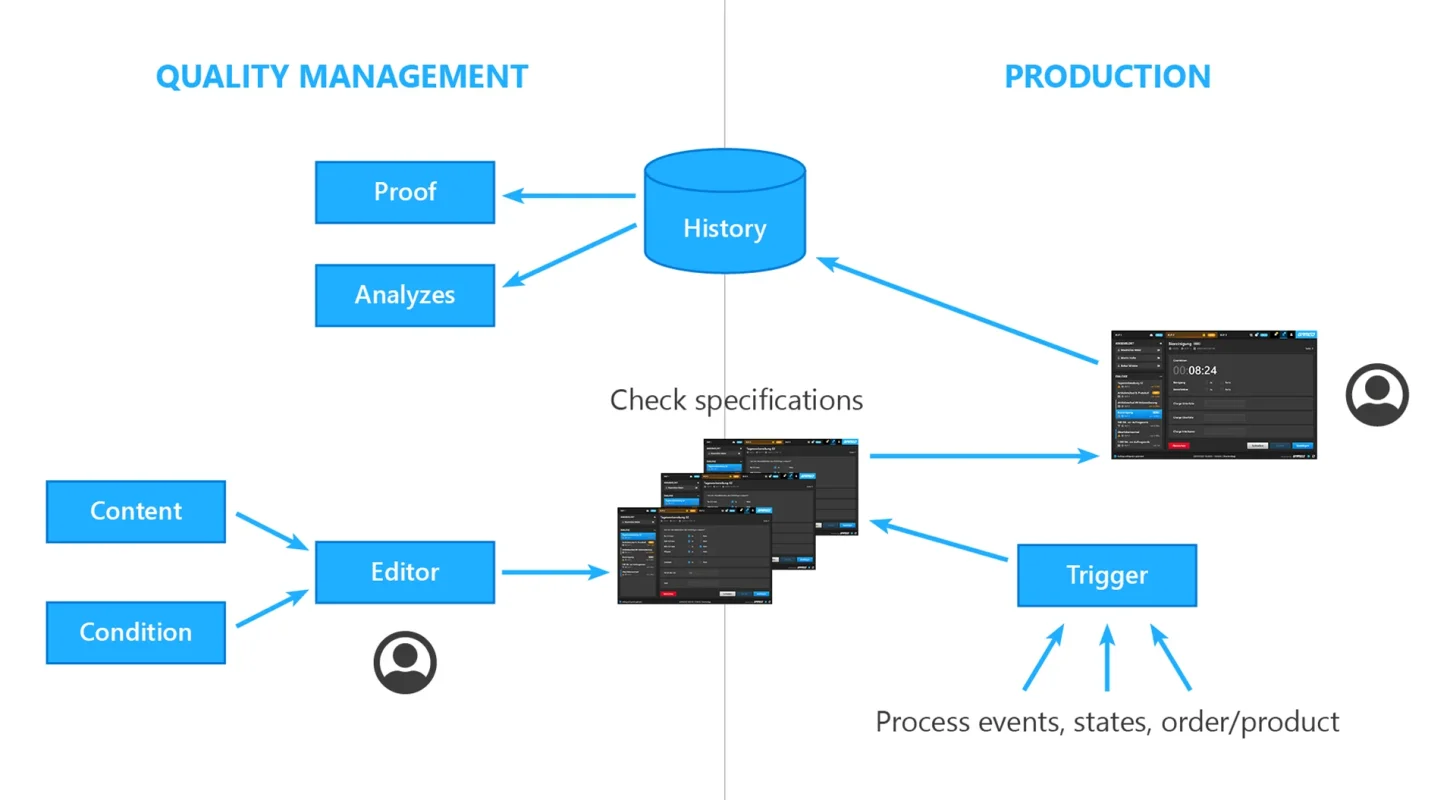

Complex processes and a large product range often make it difficult to carry out checks correctly and completely. Quality Assistant offers users significant support and security. This flexibly configurable tool manages instructions and inspections throughout the entire manufacturing process – promptly, transparently and cost-effectively.

All production events and conditions required for due date determination are incorporated into our OEE Analyser, thus Quality Assistant offers an ideal complement to the central QM system: Target values can be adopted and incorporated into inspection specifications.

The Benefits at a Glance

- Reliable, timely processing of checks

- Free definition of check specifications and due dates

- Proof of conformity for customers and audits

- Reduced workload for production staff

“Quality Assistant ensures that all planned checks are carried out reliably. The 4-eyes principle, which is often necessary, can be optimized in this way or, in certain cases, can be omitted due to direct validation.”

Corina Bruckbauer Head of Quality Management

I Will Be Happy to Help You

Philipp Seibald

Head of Business Development